There have been a number of changes to this circuit since i started, and it looks like i should really re-design my LED blinking circuitry before going much further.The biggest change was switching from two 1.3V battery cells in series, for a system voltage of 2.6V, to one or two batteries in parallel, giving a system voltage of 1.3V or so. To reach a charging voltage of 2.6V i was going to up-convert my coil voltage to 5V with a

boost converter, and use that to charge the batteries. Ive since changed all of that, and now charge my batteries directly from the coils at 1.3V. I still have a boost converter after the batteries, as all of my LED drive circuitry was designed for 5V operation.

What i'm hopping to do is remove the boost altogether, and just run everything off of a single cell voltage of 1.3V. This is quite do-able, but will mean a re-design of the LED circuitry. Additionally, new parts need to be found that can operate with a 1V supply rail.

|

| LTSpice simulation for my new oscillator |

The first part to replace is the

555 Timer that i'm using as an oscillator. Its hard to find a version of this chip that can operate at such a low voltage. Additionally, i don't need all the capabilities of a 555, i just need an astable circuit. One of the simpleness ways to do this is with a

Relaxation Oscillator, built using a

comparator or an

op-amp. Since i only have a single supply rail my circuit is slightly different than some. Ive basically just added a

voltage divider (R1 and R2) to re-zero the input so that everything works as expected. This seems to work fine... so ill use it. The benefit here is that the MAX4289 op-amp that i'm using can run off of a 1V supply, while the 555 i was using needed 3V or so. Additionally, its much simpler.

|

| Oscillator output, with the load varied between 100kOhms and 1kOhms |

I tested the designed oscillator with a few loads, just to make sure that I wont have to add a buffer stage to its output. It looks like as I swept the load between 100kOhms and 1kOhms (13uA to 1.3mA) the oscillation frequency only changed slightly. This is OK, so ill just use the circuit as-is.

The rest of my logic (to make the LED's blink in two different patterns) can be slightly simplified, but ill use basically the same chips. Currently I'm using the NC7S family, which needs at least 3V supply voltage, so ill just switch to the NC7SP family of chips, which can run off of 0.9V. The revised schematic looks something like this,

|

| New Schematic using 1V logic. |

Here, the boost converter just drives the LED's, while everything else is 1V logic. To deal with this, i may also need to change the LED string switches (U7 and U9), so I'm ordering some low voltage

MOSFET's just in case i need to replace the

BJT's I'm using now.

I went ahead and modified the old layout as well, here is an updated version.

|

| New layout to go with the new schematic. |

Ive made a few important changes here:

- There is only a single battery now, so the majority of the layout sits on top of this. This is about as small as this design will get as long as I'm using a AAA battery.

- The controlling switches have been moved to the LED board, so they will still be accessible if i decide to put the battery in the seat post as I've been planning.

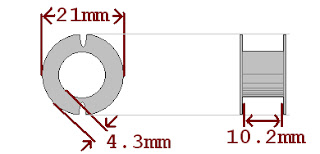

- Finally, the LED board itself has a new shape. I measured the back of my current bike seat, and if everything goes well this new shape should fit nicely between the rails at the back of the seat.

Thats about it. Ill send for the new board today and order the parts in the next few days. If all goes well i should get the new boards back next Monday or so.